There are four different types of butcher block construction:

-

Edge grain

-

End grain

-

Face grain, sometimes referred to as wide plank.

- Blended grain

Each construction style involves a different orientation of the wood planks used to build the butcher block. View each style below and click to learn more about how they are constructed.

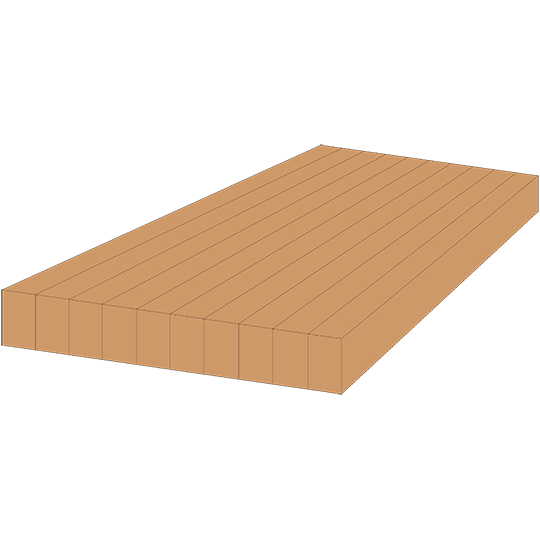

- Edge Grain Construction

Edge grain shows the wood’s edges, or the sides, of the butcher block.

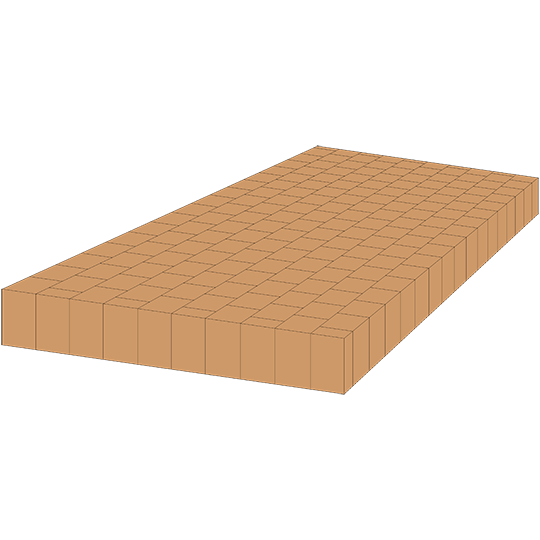

- End Grain Construction

End grain showcases both ends of the wood.

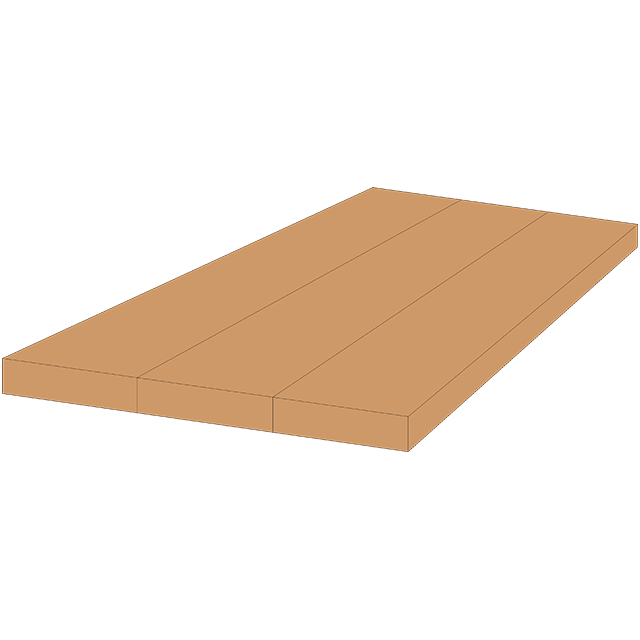

- Face Grain Construction

Face grain construction shows the faces on either side of the butcher block. This style has also earned the name “wide plank."

Edge Grain Countertop Construction

Edge grain countertops are made with long, continuous strips of wood that are glued together with the edge grain facing up using a water-resistant glue. The width of each strip typically measures 1-1/16”. Edge grain countertops can be produced in any thickness up to 4-½” thick.

Edge grain is often confused with blended countertops because they both use long strips of wood. However, the strips of wood used in a blended style are finger jointed, which means that they use multiple strips to make up the length of the board.

This construction differs drastically from edge grain, because edge grain countertops use one long continuous strip for each length of the board. While this makes them more expensive to manufacture, they are generally stronger than blended countertops.

End Grain Countertop Construction

End grain butcher block countertops are constructed using small blocks of wood each with the end grain facing up. Like other wood countertops, a water-resistant glue is used to hold them together. The size of each end grain block measures 1-½” x 1-½”.

End grain countertops can be produced in any thickness up to 4-½” thick. These countertops are unique in both their style and shape due to their composition. In addition, end grain butcher block is very resistant to cuts. This quality can help preserve your knives better than edge grain or face grain butcher blocks.

Face Grain Countertop Construction

Face grain countertops are constructed with wide, solid wood pieces that are glued together with their face grain facing up using a water-resistant glue. The width of each plank varies between 3” to 8”. Wide plank countertops can be produced in any thickness up to 1-¾” thick.

The max thickness is much lower than in other construction styles, because wide plank boards that display the face depend on the thickness of the board of wood it comes from. Edge grain and end grain styles do not have this restriction, because they do not display the face grain. They can use the full width or length of the board, allowing for a far greater thickness than wide plank countertops.

Due to the countertop construction, wide plank countertops are most often called face grain countertops. They give a beautiful representation of the face grain of the wood.

Blended Grain Construction

Blended grain counter tops are crafted from 1" wide strips of wood in random lengths, joined securely using a finger jointer and water-resistant glue. To ensure a seamless look, the outside edge features a solid strip of wood, concealing the finger-jointed sides.